How DTG Printers Ensure Consistent Quality

Share

DTG printers deliver sharp, vibrant, and reliable prints, which are crucial for customer loyalty and business growth. Here's how they maintain consistent quality:

- Daily Maintenance: Tasks like nozzle checks, ink monitoring, and cleaning prevent issues.

- Advanced Technology: Automated features like color calibration and real-time monitoring ensure precision.

- Organized Print Rooms: Clean, dust-free environments improve print quality and extend equipment life.

- Strict Quality Control: Regular testing and calibration keep colors accurate and prints flawless.

- Scalability: High-speed systems handle single or bulk orders without compromising quality.

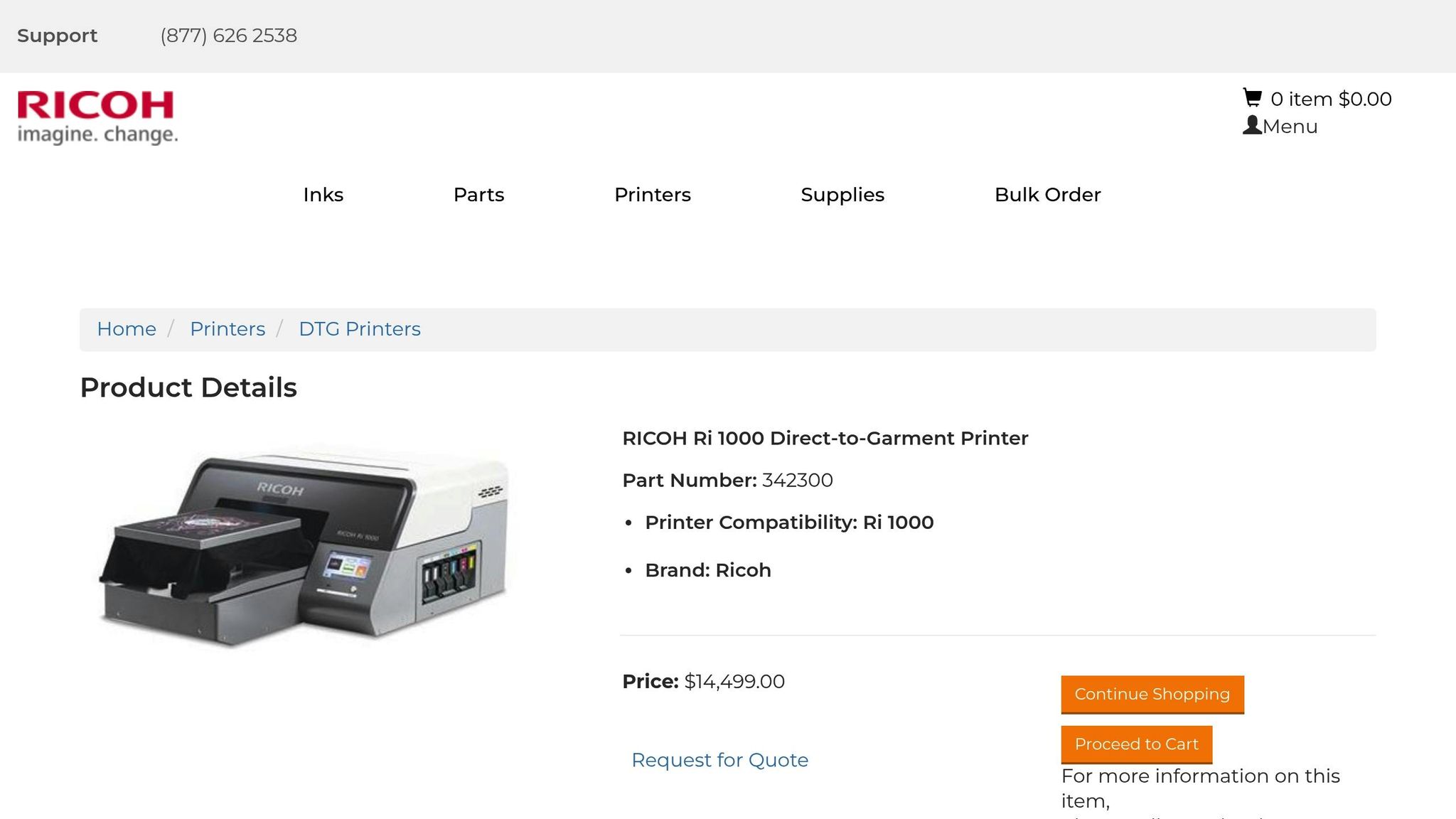

Expert Printer Maintenance Tips for Your Ricoh RI-1000 DTG!

Equipment and Process Standards

Ensuring consistent print quality requires sticking to strict equipment standards and reliable processes. A proper setup and regular upkeep make sure every print meets expectations.

Daily Printer Maintenance Steps

Daily maintenance helps prevent issues before they arise:

- Morning Nozzle Check: Verify all print heads are working properly.

- Print Head Cleaning: Clear away dried ink or debris.

- Ink Level Monitoring: Check ink levels to avoid interruptions.

- Waste Tank Inspection: Empty as needed to prevent overflow.

- Belt Cleaning: Remove lint or debris from the printer belt.

Print Head and Platen Setup

The setup of the print head and platen plays a big role in achieving consistent results. Key steps include:

- Adjusting print head height to ensure proper clearance, as per the manufacturer's guidelines.

- Verifying platen levels with digital tools.

- Calibrating print head alignment.

- Checking the white ink circulation system.

- Monitoring print head temperature.

Even small misalignments can affect quality. Regular calibrations ensure everything runs smoothly, allowing automated systems to handle the rest.

Automated Quality Controls

Modern DTG printers come equipped with automated features to maintain quality throughout production. These include:

- Real-Time Print Monitoring: Sensors catch issues as they happen.

- Color Calibration: Automatically matches colors for consistency across prints.

- Print Head Maintenance: Scheduled cleaning cycles keep print heads in top shape.

- Temperature Control: Monitors and adjusts environmental conditions.

These automated tools work alongside manual checks to ensure high-quality prints, no matter the order size.

Print Room Requirements

A clean and organized print room is crucial for maintaining consistent DTG print quality. Keeping the workspace tidy not only helps avoid contamination but also ensures your printer operates at its best. These steps work alongside equipment and process maintenance to deliver top-notch results.

Keeping a Clean Workspace

A clutter-free and clean environment reduces the chance of contaminants affecting your prints. Here’s how to maintain it:

Daily Cleaning Tasks

- Use lint-free cloths to wipe down surfaces.

- Vacuum floors with equipment designed for fine particles.

- Remove dust from printer surfaces.

- Properly dispose of waste materials.

- Regularly check and maintain air filters.

Organizing Your Workspace

- Set up specific areas for garment preparation.

- Keep garment prep and printing zones separate to prevent cross-contamination.

- Store blank garments in sealed containers or spaces.

- Cover equipment when not in use.

- Ensure walkways are clear to minimize dust movement.

Managing Air Quality

- Install air purifiers to reduce airborne particles.

- Replace air filters on a routine schedule.

- Use positive air pressure systems where needed.

- Limit access to the print room to reduce contaminants.

- Perform air quality checks periodically.

A clean and well-organized print room not only enhances print quality but also extends the life of your equipment and lowers the need for frequent maintenance. Controlling the environment is a key part of maintaining high standards throughout the printing process.

sbb-itb-121f3a0

Quality Control Methods

Automated quality controls are just the start. Methods like precise color management play a big role in ensuring consistent print results. A strong color management system helps maintain accurate color reproduction and keeps output consistent, even during large-scale production.

Here are some key practices for success:

- Regular calibration of digital equipment to keep color profiles accurate.

- Frequent updates and checks of color settings to ensure every order meets the required standards.

- Detailed documentation of calibration and quality checks to quickly spot and fix any issues.

These steps help maintain consistent quality, build customer confidence, and support long-term business success.

Print-on-Demand Business Growth

Direct-to-garment (DTG) printing makes it possible to scale custom apparel production while maintaining consistent quality. Print-on-demand services use cutting-edge digital printing tools and strict quality checks to help brands grow without compromising their standards.

Working with Wallflower Merch

Print-on-demand has revolutionized how custom apparel is created. Wallflower Merch employs high-speed DTG systems like the M&R Polaris to produce over 5,000 unique prints daily. These systems allow businesses to scale from producing a single item to thousands, all while avoiding the quality issues often linked with bulk production. Alongside advanced printing, their streamlined digital processes ensure smooth and efficient order fulfillment.

Online Store Integration

Efficient e-commerce integration is a key factor in operational success. Wallflower Merch’s experienced Shopify development team, with over a decade of expertise, collaborates with businesses to build and optimize online stores for hassle-free order management. Additionally, strategically located warehouses and optimized shipping routes help ensure that prints arrive in excellent condition.

| Quality Control Element | Impact on Business Growth |

|---|---|

| Advanced DTG Technology | Allows businesses to scale from single prints to large orders without compromising quality |

| Integrated Systems | Ensures accurate communication of print details throughout the production process |

| Strategic Fulfillment | Protects print quality during shipping and handling |

Conclusion: Maintaining Long-Term Print Quality

Let's recap the essentials for ensuring consistent DTG print quality over time, building on the processes and controls discussed earlier.

Key Takeaways

Maintaining high-quality DTG printing requires a combination of advanced equipment and careful oversight. For instance, the Hello Polaris DTG system consistently delivers quality even at volumes exceeding 5,000 prints daily.

Here are the core elements that support reliable results:

- Cutting-Edge Equipment: Industrial-grade DTG systems with automation for precision.

- Regular Quality Checks: Routine testing and documentation to catch issues early.

- Balanced Workflows: Managing production volume without compromising standards.

Scaling Without Sacrificing Quality

To grow your custom apparel business while maintaining print quality, consider working with a trusted print-on-demand partner.

Wallflower Merch is a great example, with over 1 million orders shipped, multiple warehouse locations, and advanced digital printing technology. They help businesses scale efficiently without quality concerns.

| Quality Assurance Focus | Impact on Business |

|---|---|

| Industrial-Grade Systems | Consistent results even in high-volume runs |

| Strategic Fulfillment Centers | Reliable and timely order delivery |

| Digital Workflow Integration | Simplifies order management and quality tracking |

Ready to take your production to the next level? Start focusing on quality-driven growth today.